Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Repair, Retrofitting and Rehabilitation Techniques for Strengthening of Reinforced Cement Concrete Structures Along with Experimental Work

Authors: Pushpendra Kumar Bachchan

DOI Link: https://doi.org/10.22214/ijraset.2024.61127

Certificate: View Certificate

Abstract

Structural strengthening of reinforced cement concrete (RCC) is very important because a large number of infrastructural assets in terms of buildings, bridges, sports stadium etc., which are lifeline for the civilized society. The repair, rehabilitation and retrofitting of concrete structures is really a challenging task, when structure has already undergone major structural damages or deterioration. The primary objective of this paper is to implement appropriate strengthening technique based on the observed damage and analysis results. This article also focuses on the effectiveness of the fibre reinforced polymer (FRP) material for repairs, strengthening, and retrofitting of the distressed RCC members. This has been brought in details in this paper along with experimental work which was successfully executed on the Project Construction Site, New Delhi, where the author of this paper was directly involved in planning and execution of job.

Introduction

I. INTRODUCTION

Civil engineering deals with designing, constructing various structures and maintaining infrastructure, such as buildings, roads, bridges, and dams. In construction site, a number of challenges faced by civil engineers in their day-to-day work, from ensuring the structural integrity of designs to addressing health and safety concerns. Understanding these challenges and finding effective solutions is very important for the success of any projects. Natural disasters such as earthquakes, tornados, and tsunamis threaten the integrity of civil infrastructure and safety of their users. In India large numbers of an old and existing buildings and bridges built which are deteriorated because of their use, age and may be due to fully consumption of design life. They typically do not have sufficient capacity to resist the forces during such catastrophes.

To increase the guarantee of the people safety, older and existing structures need to be repaired, maintenance and rehabilitation to prevent their collapse. Retrofitting an old and existing building, which is considerably more cost-effective than the constructing a new building. It provides an opportunity to upgrade the overall performance, efficiency and sustainability of an old and existing building. Efficient methods need to be developed for structural repair and strengthening. The rest of the paper is divided as follows: causes of deterioration in buildings are presented Sect. II. In Sect. III, Experimental works and results are described and in the end, the conclusions and recommendations is discussed.

II. CAUSES OF DETERIORATION IN BUILDINGS

A. Design and construction Flows

The performance of concrete structures depends on well defined design of concrete structures. This results less deterioration in similar condition in comparison with poorly designed concrete. Cracking is the most common defects in concrete. It can be caused by high water-to-cement ratio, improper curing methods, inadequate substrate or subbase preparation, poor concrete consolidation, timing of control-joint installation and many other different placement factors. Cracking can also be caused by design-related issues such as inadequate reinforcement or insufficient control-joint spacing.

B. Environmental Effects

In concrete structures, micro-cracks are found. It is the source of access of moisture and atmospheric carbon-dioxide into the concrete, which attack reinforcement and react with different ingredients of concrete. Structures of concrete will deteriorate faster in aggressive environment and life of concrete structures will be severely reduced.

C. Use of Poor Material Quality

Various tests, as specified in the IS codes are used to test the quality of materials which is further used in construction. Alkali-aggregate and Sulphate attack result in early deterioration. Clayed materials in the fine aggregates may weaken the mortar-aggregate bond, and reduce the strength.

D. Supervision Quality

Construction work should be carried out as per the specifications. The performances of concrete structures depend on the quality of concrete and method of concreting and curing etc. For that reason, it is very important to understand and find out the reasons, why the concrete structures fails or cracks. The occurrence of cracks can be reduced by improving the mixture of concrete, improved laying practice, and suitable weather condition and accurately managed curing.

E. Deterioration due to Corrosion

- Spalling of concrete cover

- Cracks parallel to the reinforcement

- Spalling at edges

- Swelling of concrete

- Dislocation

III. EXPERIMENTAL WORK

The main scope work included assessing structural condition of existing reinforced cement concrete (RCC) structure at the Project Construction Site, New Delhi through visual survey and non-destructive testing (NDT). During the meetings held with the contact officers, two phases of the project were made: (a) first phase: visual survey and NDT, and (b) second phase: only if requirement is felt from the first phase of the project, (i) structural analysis of the existing structure based on available drawings and data. For gravity as well as seismic loads by using structural analysis software such as SAP/ STAAD/ ETABS/ NISA, etc. (ii) suggestions and designing retrofitting scheme for the structure if it demands as per relevant Indian standard (IS) codes. Preparation and submission of detailed estimates, bill of quantities (BOQ), and specifications for retrofitting scheme.

The first phase was undertaken and completed; the report thereof is shared with the client for their use. Upon insistence of the contact officers to undertake the scope work in the second phase of the project as well, it was initiated and informed to the client accordingly, though it was mentioned in the paperwork, but was made out of the scope in first phase in the meetings.

A. First Phase: Conclusions Of Overall Testing Program

- Ultrasonic Pulse Velocity Test: The readings in this case are in range of 1.09 km/sec to 4.27 km/sec and the average reading is 2.46 km/sec. The average reading indicates ‘Doubtful’ quality of concrete [as per IS 13311 (Part 1): 1992].

- Rebound Hammer Test: The readings in this case are in range of 12 MPa to 45 MPa and the average reading is 26.21 MPa, since the average readings range between 21 MPa to 42 MPa, which indicates ‘Average’ to ‘Fair’ quality of concrete [as per IS 13311 (Part 2): 1992].

- Carbonation Test: Depth of carbonation in RCC members is in range from 5-30 mm. The average depth of carbonation is 14.1 mm.

- Half Cell Potential Test: The average readings in this case are in varying range of -383 mV to -179 mV, which indicates that the probability of active corrosion is approximately 50%.

- Core Compression Test: The equivalent compressive strength of concrete core is 16.04 N/mm2.

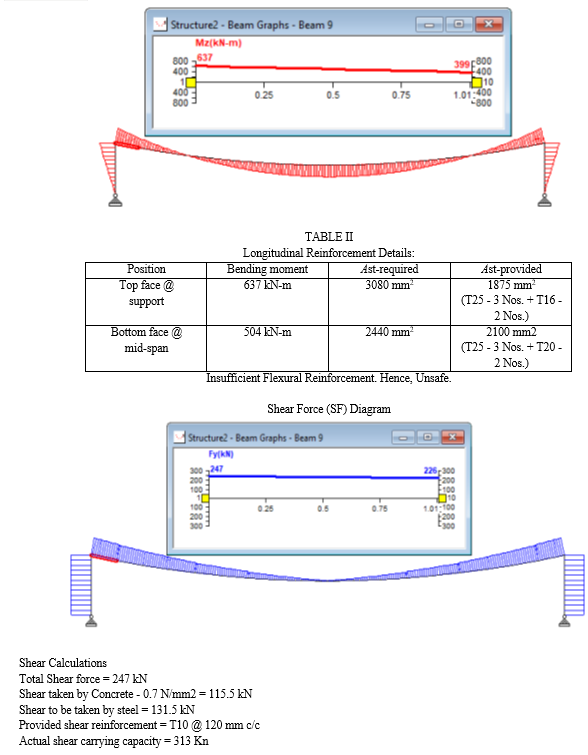

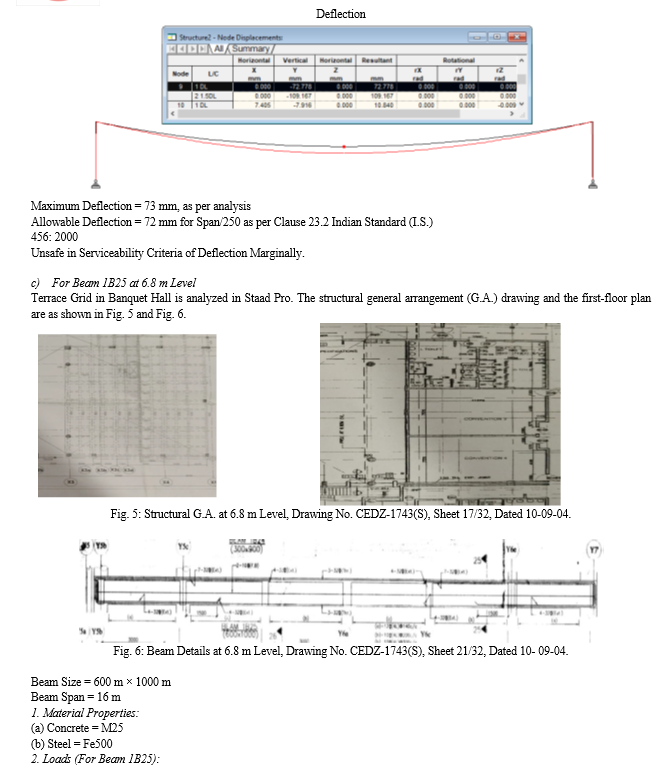

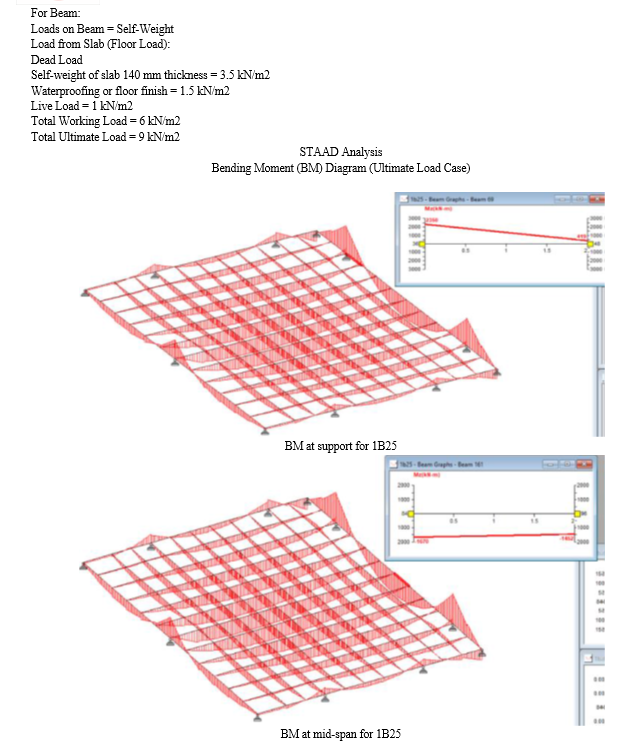

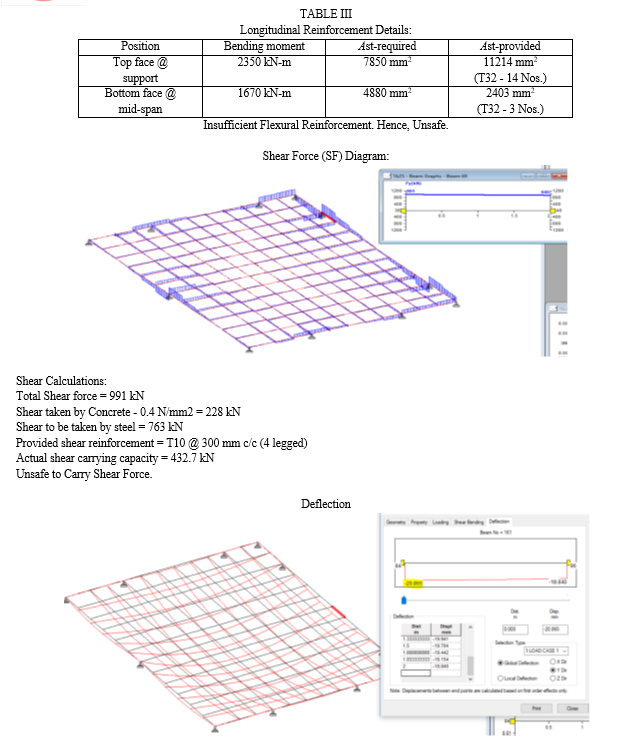

B. Second Phase: Structural Analysis And Design Assessment

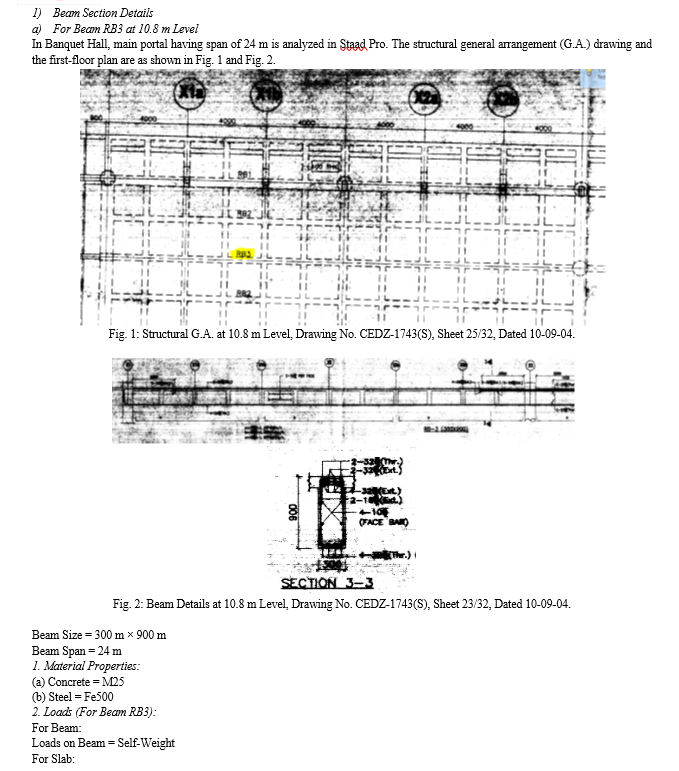

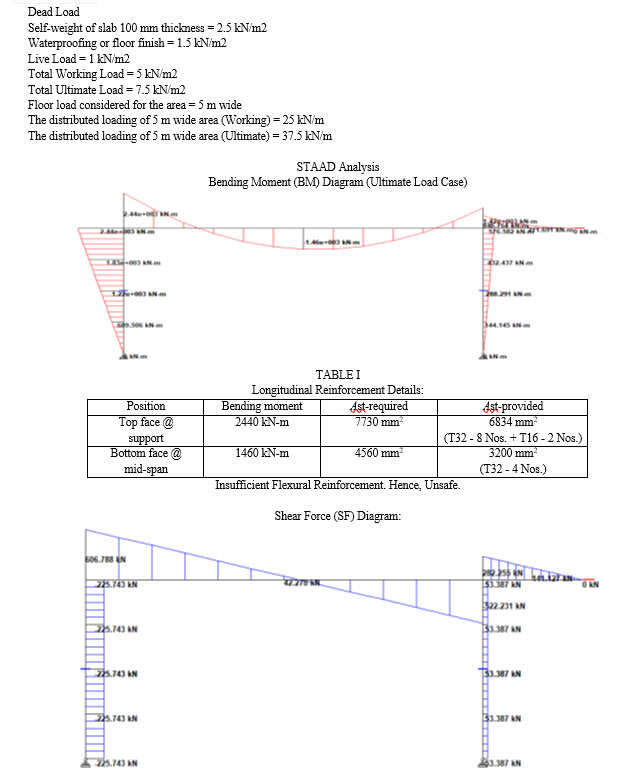

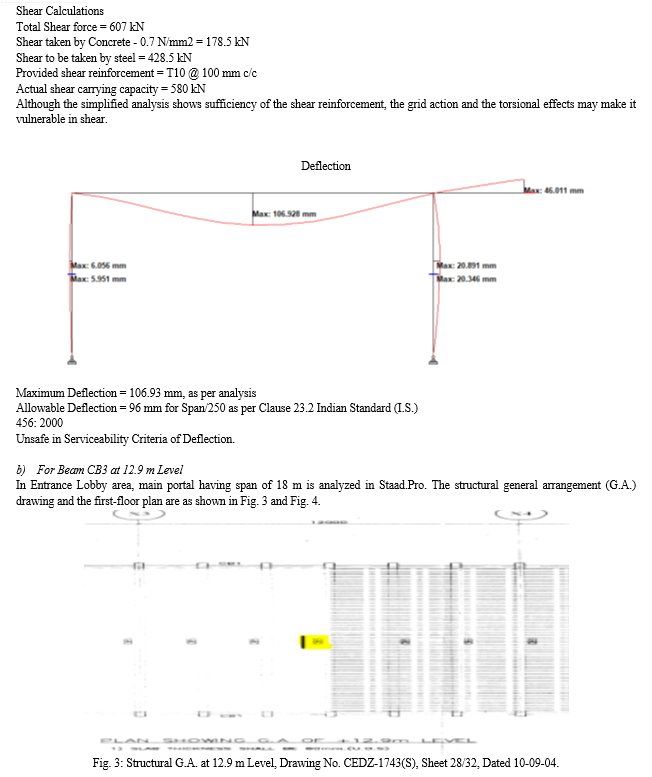

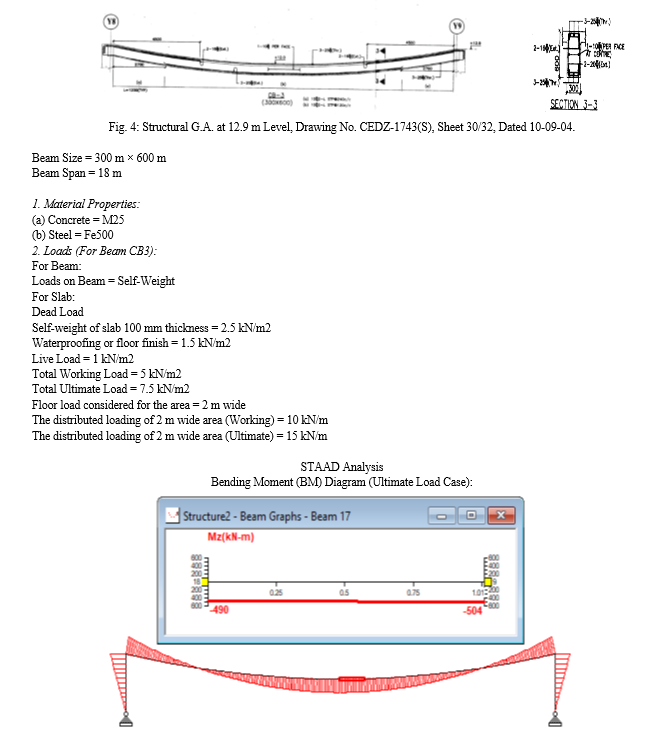

Second phase of the works was undertaken. Under the given circumstances, in such an exercise, the input details are taken from the investigations carried out in the first phase of the works reported earlier and structural models have been generated in the commercial software, STAAD as deemed necessary on case to case basis. The reports of first phase and second phase therefore are required to be read together. The design calculations are subsequently carried out and assessment is made on the adequacy of the structural members concerned, which have experienced distress. The following are structural analyses of the existing structures, by using structural analysis software, STAAD.

Maximum Deflection = 20.86 mm, as per analysis

Allowable Deflection = 64 mm for Span/250 as per Clause 23.2 Indian Standard (I.S.)

456: 2000

Notes: The analysis results should be correlated with the observed behaviour of the structural members. Appropriate strengthening measures should be undertaken, if required.

Conclusion

Some of the RCC members are found to be deficient their structural design. The distress observed and reported in Part-1 of the report, in the First Phase, can be related to these structural deficiencies mentioned above. Hence, in the current situation, immediate structural strengthening and tenantable repairs are essentially required. The analysis carried out for the typical selected members are indicative in nature. The agencies to be appointed for the strengthening should carry out a detailed evaluation of each member and implement appropriate strengthening technique based on the observed damage and analysis results. It is recommended that the enhancement in the structural properties due to the adoption of any strengthening strategy should be demonstrated by design calculations and/or on-site tests after execution, as applicable. Repairs and strengthening are suggested. While repairing all the distressed structural members and other related members need to prop for safety. The RCC elements in which extensive cracking, sapling of concrete and reinforcement is found exposed shall be repaired as per methodology and guidelines suggested by Indian standard (I.S.) codes, and separate detailed design of the structural strengthening be carried out. The repair and strengthening works will be able to improve service-life and safe occupancy of the concerned structures. In certain areas where major damages have been observed, while repairing those shall be strengthened by using appropriated \"retrofitting\" (code compliant) methods as well. The certification of habitation shall be only valid after attending all structural strengthening and repair works. Afterwards, it is advised to carry out regular structural health condition survey and periodic maintenance of the buildings for safe habitable conditions. The structural strengthening and repairing shall be carried out by specialized structural repair contractor(s). For the project in concern, a detailed investigation is subsequently carried out to assess the effectiveness of the fibre reinforced polymer (FRP) material composites to be employed for repairs, strengthening, and retrofitting of the distressed RCC members. It is concluded that the FRP composite materials will be able to effectively address the issues of distress observed. Then, the members requiring immediate attention have been identified and a detailed bill of quantities (BOQ) is prepared. Based on the repair methodology, the BOQ evaluated, and the assessment of the structural condition of the existing RCC structures provided earlier, it is feasible and highly recommended to execute the structural repairs/ strengthening/ retrofitting program at the concerned structures at the Project Construction Site, New Delhi, India. This report should not be considered as a fact-finding report.

References

[1] HalilSezen, M.Asce (2012), \"Repair And Strengthening of Reinforced Concrete Beam-Column Joints With Fiber-Reinforced Polymer Composites\" Journal of Composites For Construction © ASCE. [2] J. Bhattacharjee (2016), \"Repair, Rehabilitation & Retrofitting of RCC For Sustainable Development With Case Studies\" International Journal (CIVEJ) Vol.3, No.2. [3] Jay H. Paul (2002), \"Repair, Renovation And Strengthening of Concrete Structures\" [4] Manish Kumar (2016), “Structural Rehabilitation, Retrofitting And Strengthening of Reinforced Concrete Structures” International Journal of Civil, Environmental, Structural, Construction and Architectural Engineering Vol: 10, No: 1. [5] S. Raja Subramaniam (2016), “A Review on Repair and Rehabilitation of Heritage Buildings” International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056 p-ISSN: 2395-0072 Volume: 03 Issue: 04. [6] Shri. Pravin B. Waghmare (2011), \"Materials And Jacketing Technique For Retrofitting of Structures\" International Journal of Advanced Engineering Research And Studies E-ISSN2249 – 8974, Vol. I, Issue I 15-19. [7] Surresh Chandra Pattanaik, E. Gopal Krishnan And Mohan Kumar(2011), \"Repair And Rehabilitation of Nehru Memorial College of K.V.G. Group of Institutions At Mangalore - A Case Study\" Paper Published In The Proceedings of International Conference Cemcon 2011 Organised By Indian Concrete Institute, Pune. [8] Handbook of Repair and Rehabilitation of RCC Buildings. [9] Mr. Pavan D. Tikate, Dr. S. N. Tande, \"Repair and Rehabilitation of Structures\", International Journal of Engineering Sciences and Research Technology, 2014, Vol. 3(Issue No. 10), PP. 511-515. [10] Mr. S. S. Chandar, \"Rehabilitation of Buildings\", International Journal of Civil Engineering Research, ISSN 2278-3652 Volume 5, Number 4 (2014), pp. 333-338. [11] Repair, Restoration and Strengthening of Buildings, IAEE Manual, Chapter 9. [12] Indian Standard: 13311:1992 (Part 1) NDT methods of Test- Ultrasonic Pulse Velocity. [13] Indian Standard: 13311:1992 (Part 2) NDT methods of Test- Rebound Hammer. [14] Prof. M. Vijayalakshmi, \"CE 2031: Repair and Rehabilitation of Structures\".

Copyright

Copyright © 2024 Pushpendra Kumar Bachchan. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61127

Publish Date : 2024-04-27

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online